Leave Your Message

Pressure control valves are essential components in various hydraulic and pneumatic systems, ensuring optimal performance and safety. Understanding how these valves work can significantly enhance system reliability and efficiency. This article delves into the intricate mechanisms behind pressure control valves, explaining their function in regulating fluid pressure and preventing system overloads. By maintaining the appropriate pressure levels, these valves not only protect equipment but also improve operational efficiency. Whether you're involved in industrial applications, automotive systems, or any other field that utilizes hydraulic technologies, gaining insight into pressure control valves is crucial. This guide will provide you with a comprehensive overview of their design, types, and applications, equipping you with the knowledge to implement and troubleshoot these vital components effectively.

Pressure control valves are essential components in various hydraulic and pneumatic systems, ensuring optimal performance and safety. Understanding how these valves work can significantly enhance system reliability and efficiency. This article delves into the intricate mechanisms behind pressure control valves, explaining their function in regulating fluid pressure and preventing system overloads. By maintaining the appropriate pressure levels, these valves not only protect equipment but also improve operational efficiency. Whether you're involved in industrial applications, automotive systems, or any other field that utilizes hydraulic technologies, gaining insight into pressure control valves is crucial. This guide will provide you with a comprehensive overview of their design, types, and applications, equipping you with the knowledge to implement and troubleshoot these vital components effectively.

Pressure control valves (PCVs) play a crucial role in various industries by regulating the pressure within hydraulic and pneumatic systems. Understanding the basics of these valves is essential for effective system management. Typically, PCVs adjust the pressure of fluids within pipelines or equipment, ensuring optimal performance and safety. According to industry reports, a surge in demand for automated pressure control systems is expected to grow by 6.5% annually over the next five years, reflecting the increasing emphasis on efficiency and reliability in industrial operations.

When selecting a pressure control valve, it’s crucial to consider factors such as the pressure range, flow characteristics, and the type of fluid being controlled. Different PCVs, including direct-acting and pilot-operated, offer distinct advantages suited to specific applications. For optimal valve performance, regular maintenance is essential. TIPS: Ensure you check the manufacturer's specifications for proper installation and operational limits to avoid malfunctions.

Properly functioning PCVs can contribute significantly to system longevity and cost savings. Regular monitoring of valve conditions can help prevent unexpected failures. TIPS: Implement a routine inspection schedule to identify wear and tear early, which can save on costly repairs and downtime. By prioritizing these practices, industries can maximize the efficiency and reliability of their pressure control systems.

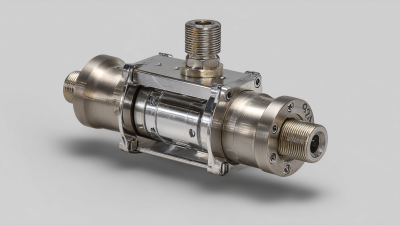

Pressure control valves play a crucial role in various systems by maintaining the desired pressure levels, preventing excess pressure which could lead to system failure. The mechanism behind pressure regulation involves a combination of components that respond to changes in pressure. When the system pressure exceeds a preset threshold, the valve automatically adjusts to reduce pressure by venting excess fluid or adjusting flow rates, thereby stabilizing the system.

In the context of automotive engineering, pressure control valves are particularly significant in turbocharging systems. Recent news highlights a major player in the automotive industry that has secured key turbocharger projects for a global manufacturer, aimed at enhancing engine efficiency while adhering to stringent emission standards. These turbochargers rely on precise pressure regulation to optimize performance and fuel efficiency. The effective functioning of pressure control valves within these systems ensures that engines operate smoothly under varying conditions, contributing to overall vehicle performance and sustainability.

Pressure control valves are essential components in various industrial applications, ensuring optimal fluid flow and system safety. These valves come in different types, including pressure relief valves, pressure reducing valves, and pressure regulating valves, each serving specific functions. For example, pressure relief valves protect tanks and vessels from overpressure, while pressure reducing valves lower the pressure of the fluid to desired levels. The global market for pressure reducing valves is projected to grow significantly, from USD 3.87 billion in 2024 to USD 5.67 billion by 2033, indicating an increasing demand driven by industries focusing on safety and efficiency.

In the context of new advancements, manufacturers are continuously innovating to enhance the performance of pressure control valves. For instance, the development of advanced hydraulic control valves allows for finer control and improved efficiency in mobile applications. This trend is critical as industries, particularly in the energy sector, lean towards cleaner technologies and more sustainable practices. The rise of the liquefied natural gas industry is a testament to this shift, necessitating robust and reliable pressure control solutions to support safe operations. As the industrial valve market is anticipated to grow from $95.58 billion in 2024 to $121.67 billion, the evolution of pressure control valves remains pivotal to ensuring safe and efficient fluid management across various sectors.

Installing pressure control valves can be straightforward if you follow a systematic approach. First, ensure you have the necessary tools and safety equipment at hand, such as wrenches, screwdrivers, and protective gloves. Begin by turning off the system where the valve will be installed, and relieve any pressure within the lines to prevent accidents. Carefully remove the old valve, taking note of the existing plumbing configuration to make the installation seamless.

Next, prepare the new pressure control valve by checking that it is compatible with the system specifications. Apply Teflon tape to the threads of the valve to ensure a tight seal. Position the valve in the correct orientation—typically with the inlet and outlet aligned with the flow direction. Secure it in place by tightening the connections, ensuring that you do not over-tighten as this might damage the valve. Once the installation is complete, restore the system pressure slowly and check for any leaks, making adjustments as necessary. This careful approach will help ensure your pressure control valves function effectively and enhance system performance.

Pressure control valves (PCVs) are vital components in various industrial systems, regulating pressure to ensure safe and efficient operations. However, like any mechanical part, PCVs can encounter issues that may compromise their effectiveness. Common problems include incorrect pressure settings, leakage, and valve sticking. According to industry reports, around 20% of maintenance costs in fluid handling systems are attributed to issues with pressure control valves, underscoring their significance in operational reliability.

To troubleshoot these common issues, it’s essential to follow some practical tips. First, regularly check the calibration of your pressure control valves to confirm they are set to the correct specifications. An out-of-calibration valve can lead to overpressure situations, risking equipment damage or failure, as noted in research by the American Society of Mechanical Engineers (ASME). Second, inspect for leaks around the valve seals and fittings; a small leak can indicate wear or damage that needs immediate attention. Lastly, ensure that the valve operates smoothly without sticking by performing routine maintenance. This can significantly reduce downtime and enhance the lifespan of the valve, as highlighted in studies from the International Society for Automation (ISA).

| Dimension | Value |

|---|---|

| Type | Spring-Loaded |

| Operating Pressure Range | 10 - 100 psi |

| Common Issues | Leakage, Fluttering |

| Troubleshooting Steps | Inspect seals, Adjust pressure settings |

| Maintenance Frequency | Every 6 months |

| Typical Applications | HVAC, Water Systems |