Leave Your Message

In recent years, the integration of Stacked Hydraulic Manifolds has emerged as a significant advancement in the optimization of fluid systems across various industrial applications. According to a report by the International Fluid Power Society, the use of stacked manifolds can reduce the overall footprint of hydraulic systems by up to 30%, while simultaneously enhancing efficiency and improving maintenance accessibility. Additionally, a study by the National Fluid Power Association highlighted that optimized hydraulic systems can lead to a reduction in energy consumption of approximately 15-25%, significantly lowering operational costs. These benefits are particularly crucial in sectors such as manufacturing, agriculture, and mobile machinery, where performance and space-saving solutions are paramount. As industries continue to seek innovative ways to enhance system reliability and functionality, understanding how to effectively implement and optimize Stacked Hydraulic Manifolds becomes essential for engineers and designers aiming to push the boundaries of fluid power technology.

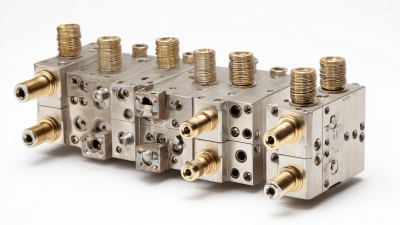

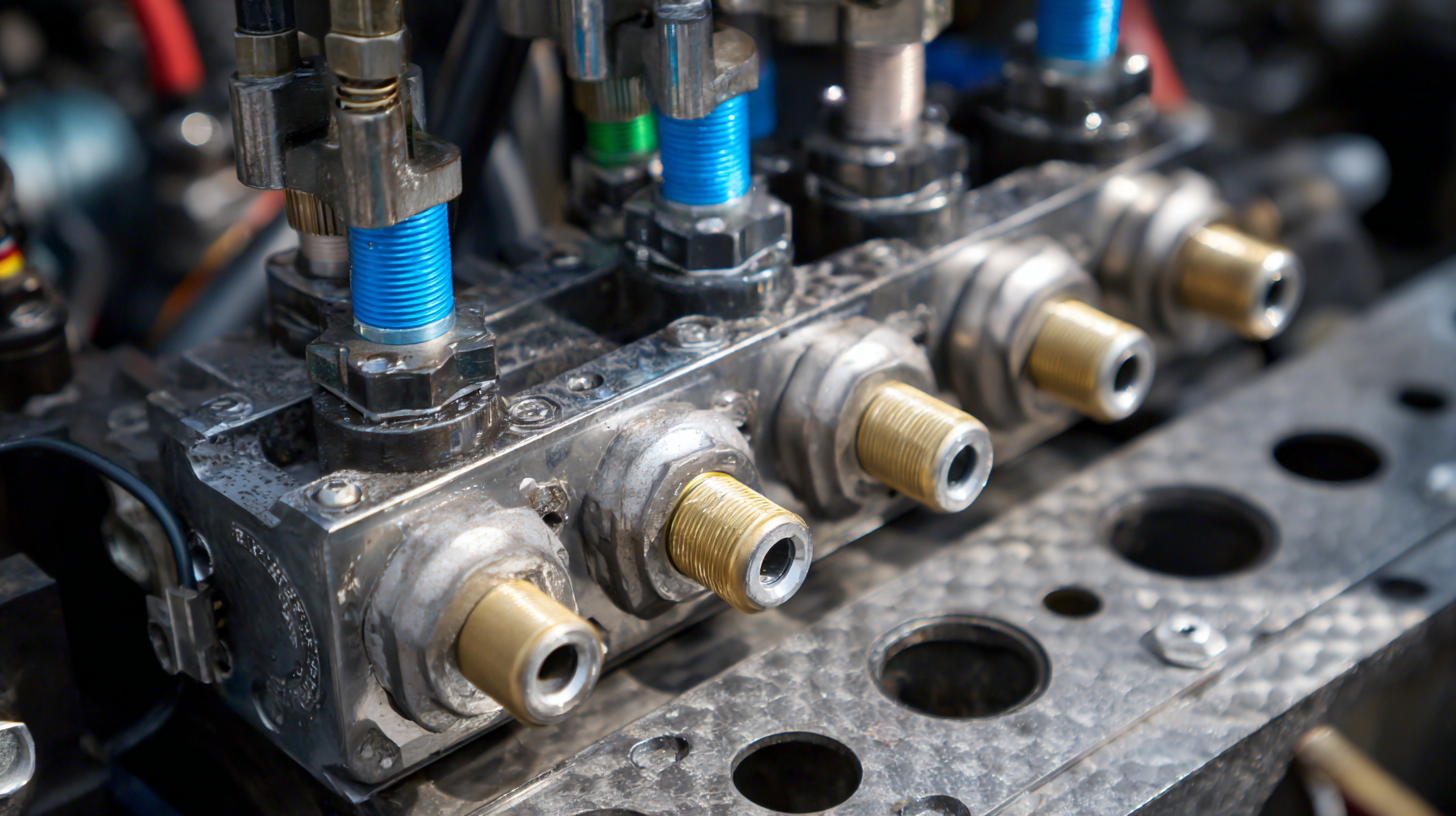

Stacked hydraulic manifolds have emerged as a pivotal component in optimizing fluid systems, offering several key advantages that enhance overall performance. One significant benefit is the reduction of space requirements. Traditional hydraulic systems can be cumbersome and take up considerable room; however, stacked manifolds consolidate multiple hydraulic functions into a compact unit. This design not only saves valuable space but also simplifies installation and maintenance, allowing for more efficient system layouts.

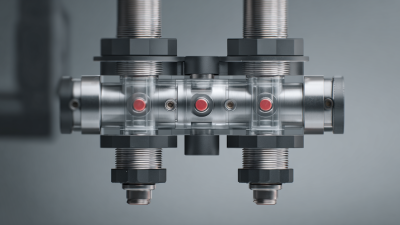

Another essential advantage of stacked hydraulic manifolds lies in their ability to improve fluid flow and reduce pressure losses. By integrating multiple control functions into a single manifold, the flow path becomes more direct, which minimizes turbulence and decreases resistance. This efficiency translates into improved response times and more precise control over system operations. Additionally, the modular nature of stacked manifolds allows for easy scalability, enabling engineers to adapt fluid systems quickly as operational demands change, thereby enhancing overall system reliability and performance.

To optimize the performance of stacked hydraulic manifolds, several essential design considerations must be taken into account. First, the flow path arrangement plays a crucial role in determining how effectively the hydraulic fluid moves through the system. Designers should strive for a layout that minimizes bends and transitions, as these can introduce turbulence and reduce overall efficiency. Additionally, ensuring that the manifold is appropriately sized for the application is vital; oversized manifolds can lead to unnecessary weight and cost, while undersized units may struggle to meet flow demands.

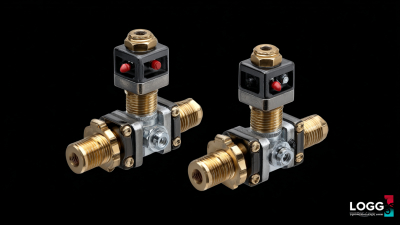

Another important aspect is the selection of materials and components. High-quality materials capable of withstanding pressure and temperature fluctuations can significantly enhance the lifespan and reliability of the manifold. Furthermore, integrating features such as pressure relief valves and flow control measures directly into the manifold design can simplify maintenance and improve system safety. Ultimately, a thoughtful approach to the configuration of stacked hydraulic manifolds not only boosts performance but also contributes to the overall effectiveness of hydraulic fluid systems.

| Design Consideration | Description | Impact on Performance |

|---|---|---|

| Flow Path Optimization | Designing an efficient route for fluid flow reduces pressure drops. | Increased efficiency and speed of operation. |

| Size and Configuration | Selecting appropriate sizes and shapes for components to minimize friction. | Improved flow rates and reduced energy consumption. |

| Material Selection | Using high-quality materials to withstand pressure and reduce wear. | Longer equipment lifespan and lower maintenance costs. |

| Ventilation and Cooling | Integrating systems for heat dissipation during operation. | Prevention of overheating, leading to optimal operation. |

| Modular Design | Creating interchangeable modules for easy upgrades and repairs. | Enhanced flexibility and adaptability to changing requirements. |

The optimization of fluid dynamics in stacked hydraulic manifolds is crucial for enhancing system performance. Recent studies estimate that by implementing advanced design techniques, system efficiency can increase by up to 20%, significantly impacting overall operational costs. One of the primary techniques involves the careful arrangement of flow paths within the manifold. An optimized flow channel design reduces turbulence and pressure drops, leading to more stable and efficient fluid flow. According to a report by the Fluid Power & System Dynamics Journal, this approach has demonstrated a 15% reduction in energy consumption for hydraulic systems.

Additionally, the use of computational fluid dynamics (CFD) for modeling and simulation plays a pivotal role in optimizing fluid behavior within manifolds. By simulating various configurations, engineers can identify the most effective design parameters that enhance fluid dynamics. Implementing such technology can lead to improvements in flow uniformity and minimized cavitation effects. The Hydraulic Institute reports that systems employing CFD-guided manifold designs achieve a consistent performance gain of about 10-12%, making it a vital tool for design engineers aiming to maximize the efficiency of fluid systems.

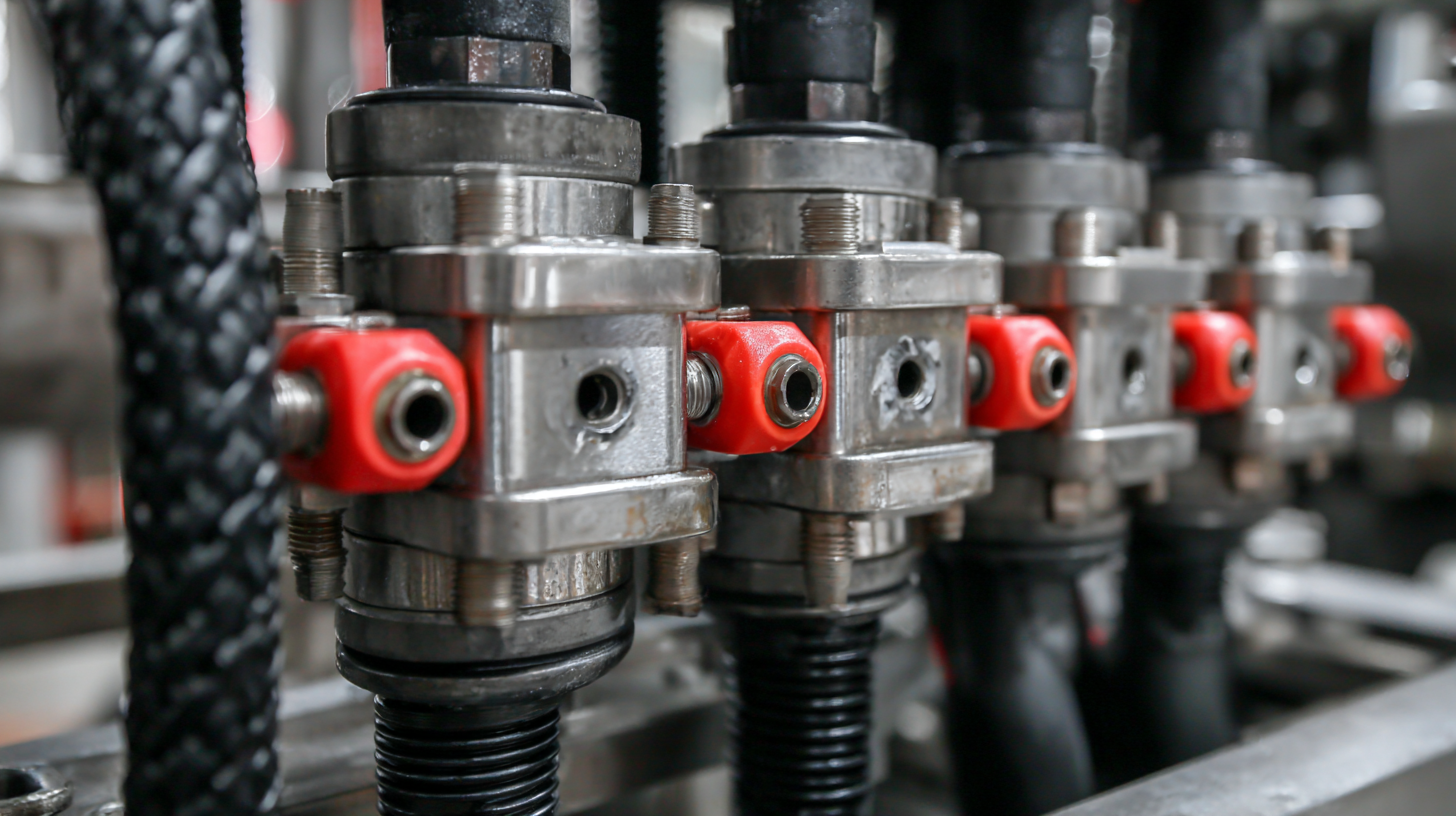

Effective maintenance and troubleshooting of hydraulic systems are essential for optimizing performance, particularly when utilizing stacked hydraulic manifolds. According to a report from the Hydraulic Institute, approximately 30% of hydraulic system failures result from inadequate maintenance practices. Regularly inspecting components such as pumps, valves, and hoses can significantly reduce downtime and enhance efficiency. Implementing a preventive maintenance schedule that includes routine checks and fluid analysis can help identify potential issues before they escalate, ultimately saving time and costs.

To troubleshoot common hydraulic system problems, technicians should first utilize diagnostic tools to monitor pressure and flow rates. Industry standards indicate that more than 70% of hydraulic failures can be attributed to improper fluid quality or contamination. Therefore, maintaining clean hydraulic fluid through effective filtration systems is critical. Additionally, keeping track of temperature fluctuations is vital; fluids become less effective at extreme temperatures, which can lead to inefficient performance and increased wear on components. By focusing on these best practices, hydraulic system operators can ensure longevity and reliability in their operations.

The emergence of innovative technologies has significantly elevated the performance capabilities of stacked hydraulic manifolds in fluid systems. According to a recent report by the Hydraulic Institute, the integration of advanced materials and manufacturing techniques has improved the efficiency of hydraulic systems by up to 30%. These enhancements are primarily attributed to the reduction of weight and improved thermal management, allowing for higher fluid flow rates without compromising system integrity.

Moreover, the adoption of smart sensors and IoT connectivity is revolutionizing how hydraulic manifolds operate. A study by the American Society of Mechanical Engineers highlights that real-time data analytics can lead to predictive maintenance, reducing downtime by as much as 25%. This proactive approach enables operators to anticipate issues before they escalate, significantly improving reliability and performance. As industries continue to embrace these technological advancements, the stacked hydraulic manifold stands out as a keystone for optimizing fluid system performance in a variety of applications.