Leave Your Message

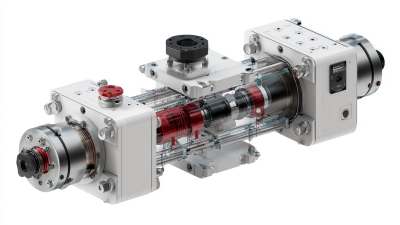

Hydraulic lock poses significant risks in various industries, particularly in heavy machinery operations. According to a report by the International Journal of Engineering Research, approximately 25% of hydraulic failures stem from this issue. Hydraulic lock occurs when air or fluid gets trapped in a hydraulic system, preventing proper movement. The consequence can be severe, leading to equipment damage and operational downtime.

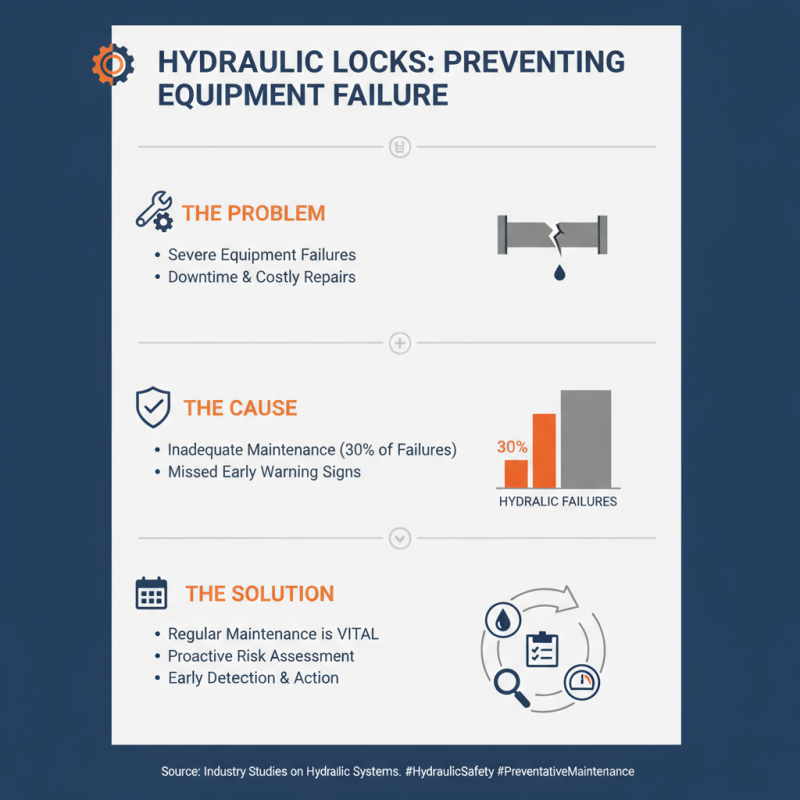

Many industries rely on hydraulic systems, making prevention crucial. A 2021 study by the Hydraulic Institute revealed that preventive measures can reduce hydraulic failure rates by up to 30%. Techniques such as regular maintenance, proper fluid levels, and pressure checks can mitigate the risk. However, many operators overlook these essential practices. This negligence can lead to costly mistakes and safety hazards.

Awareness of hydraulic lock is vital. The consequences of this problem extend beyond equipment failure; they can also jeopardize worker safety. Key indicators of hydraulic lock should be monitored closely. Ignoring these signs could extinguish productivity and cause equipment failure. Therefore, understanding hydraulic lock and implementing best practices is essential for smooth operations.

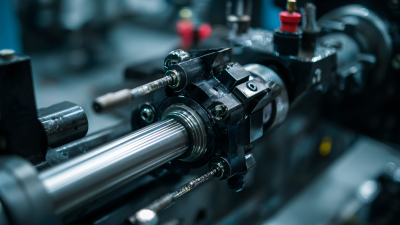

Hydraulic lock occurs when a fluid is trapped in a cylinder. This situation can lead to severe mechanical failures. Even a small amount of fluid can create significant pressure. Equipment can seize up, resulting in costly downtime. Workers could be injured during sudden malfunctions. Understanding hydraulic lock is crucial for anyone using hydraulic systems.

The implications of hydraulic lock are far-reaching. It can result in damage to hydraulic components. Even regular maintenance checks may overlook this risk. Operators must be trained to recognize signs of hydraulic lock. They should monitor for unusual noises or vibrations. Failure to address these signs can lead to catastrophic outcomes.

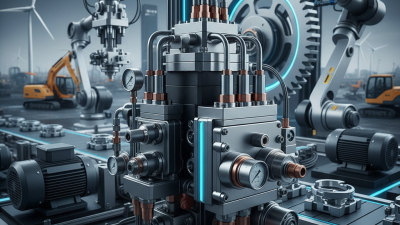

Prevention requires proactive measures. Conducting routine inspections is vital. Operators should verify fluid levels and monitor for potential leaks. However, it's easy to forget simple checks in a busy environment. A culture focusing on safety and awareness can help. Ensuring that everyone understands the risks associated with hydraulic systems is essential.

Hydraulic lock can be a serious issue in various types of equipment. Understanding its common causes is crucial for effective prevention. One major cause is moisture contamination. When water enters the hydraulic system, it can create ice or steam, leading to blockages. This often happens in colder temperatures when condensation occurs.

Another significant factor is improper fluid levels. Too much or too little hydraulic fluid can disrupt the system. This creates pressure imbalances, making components prone to lock. Regular checks are essential to maintain optimal fluid levels. Equipment operators sometimes overlook these checks, leading to unexpected failures.

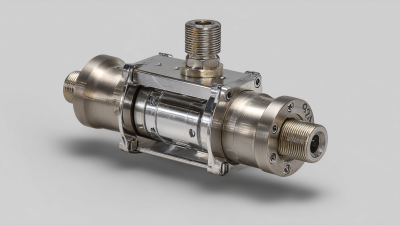

Lastly, using the wrong fluid can also lead to problems. Not all fluids are compatible with every system. Using the incorrect type can cause foaming or other performance issues, resulting in hydraulic lock. Operators should ensure they are using the right fluid specified for their equipment. Maintaining a clean and compatible hydraulic system requires diligence and attention to detail.

Hydraulic lock is a significant concern in various industries. When equipment fails due to fluid being trapped in a cylinder, severe consequences follow. Data shows that around 25% of maintenance issues stem from hydraulic failures, highlighting the need for robust prevention strategies. Regular maintenance checks can help catch potential problems early. Inspect seals and hoses frequently to reduce the risk of leaks leading to lock-up situations.

Implementing proper fluid management practices is essential. A study indicated that using the wrong fluid type increases the chances of hydraulic lock by up to 30%. Educating team members on correct fluid handling techniques is crucial. Consistent training sessions can ensure everyone is on the same page. Real-time monitoring of pressure levels can also alert operators to anomalies before they escalate.

While these measures are effective, oversights still occur. Some operators may neglect routine checks, thinking everything is fine. This mindset can lead to catastrophic failures. Hence, fostering a culture of safety and vigilance should be a priority. Establishing a reporting system for anomalies can further improve hydraulic system reliability, reducing the frequency of costly repairs.

Hydraulic lock is a serious issue in machinery. Recognizing the signs and symptoms can prevent costly repairs. One common symptom is unusual sounds during operation. These noises often signal trouble. If you hear clanking, grinding, or even silence where there should be noise, investigate further.

Another key indicator is inconsistent performance. Machines may hesitate or stall unexpectedly. This erratic behavior often suggests fluid trapped in the system. In some cases, operators might notice increased pressure readings. Monitoring gauges regularly can help catch these issues early. Always pay attention to what your machine is telling you.

Vibration might also indicate hydraulic lock. Excessive shaking or movement can reveal underlying problems. Operators should remain vigilant and responsive to these signs. Often, it's easy to overlook minor issues until they escalate. Recognizing these symptoms is essential for effective maintenance. Consider keeping a log of any abnormal behavior for reference and reflection.

Hydraulic lock can lead to severe equipment failures. Regular maintenance is vital. Studies show that nearly 30% of hydraulic system failures occur due to inadequate maintenance practices. Identifying and addressing potential risks must be a priority.

Routine inspections can help catch issues early. Checking fluid levels and monitoring for leaks are essential. According to a report by the International Fluid Power Society, maintaining proper fluid cleanliness can reduce failure rates by up to 25%. Implementing a schedule for these inspections ensures consistency.

Training staff is equally important. A well-informed team can recognize early signs of hydraulic lock. However, often, organizations neglect training due to budget constraints. Investing in personnel education can prevent costly downtime. Simple practices like replacing filters regularly can mitigate risks significantly.