Leave Your Message

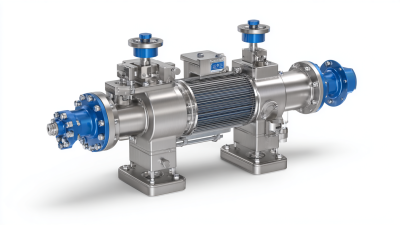

In the realm of industrial applications, ensuring safety and efficiency is paramount, and one key component that plays a crucial role in achieving this is the Pilot Operated Relief Valve. These sophisticated valves are designed to regulate pressure within systems, preventing over-pressurization and potential damage to equipment. By understanding the functionality and mechanics of Pilot Operated Relief Valves, engineers and operators can optimize their systems for better performance, reliability, and compliance with safety standards. This blog will delve into the intricacies of these valves, exploring their design advantages, operational principles, and best practices for implementation across various industrial settings. Whether you are a seasoned professional or new to the field, gaining insight into Pilot Operated Relief Valves will not only enhance your knowledge but also contribute to safer and more efficient industrial processes.

Pilot operated relief valves (PORVs) play a crucial role in enhancing industrial efficiency by providing reliable overpressure protection in various applications. Unlike conventional relief valves, PORVs utilize a pilot mechanism to control the opening and closing of the main valve, allowing for more precise pressure regulation. This advanced technology can cut system pressure variations by up to 50%, according to the 2021 Valves and Actuators Market report by MarketsandMarkets. Such stability is essential for processes that require strict adherence to pressure levels, reducing the risk of equipment failure and downtime.

In addition to pressure stability, the energy efficiency of pilot operated relief valves is noteworthy. The American Society of Mechanical Engineers (ASME) notes that the use of PORVs can lead to a reduction in energy consumption by optimizing the valve's response time and minimizing the operational load on pumps and compressors. This is particularly beneficial in large-scale industrial settings, where even slight improvements in efficiency can translate into significant cost savings. Moreover, the maintenance requirements of PORVs are typically lower than their non-pilot counterparts, further contributing to operational efficiency and reduced lifecycle costs.

This chart illustrates the performance metrics of Pilot Operated Relief Valves in industrial applications. It displays critical data such as flow rate, set pressure, operating range, response time, and leakage rate, highlighting their importance for operational efficiency.

Pilot operated relief valves (PORVs) are crucial for maintaining pressure stability across various industrial applications. By utilizing a pilot signal to control the main valve, these devices provide enhanced regulation of system pressure, which is vital in industries such as oil and gas, chemical processing, and power generation. The benefits of pressure regulation are manifold, including improved safety, reduced equipment wear, and increased operational efficiency.

In the oil and gas sector, for example, PORVs prevent excess pressure buildup that could lead to catastrophic failures. Similarly, in chemical processing, they help manage the delicate balance of pressure required to safely handle volatile substances. As industries increasingly focus on automation and efficiency, the role of pilot operated relief valves becomes even more significant, offering precise control that bolsters both safety and productivity.

**Tip:** Regular maintenance of PORVs is essential. Ensure that the valves are tested periodically to verify their functionality and responsiveness to pressure changes.

**Tip:** When selecting a PORV, consider the specific pressure ranges and flow rates of your application. This will ensure optimal performance and longevity of the valve.

**Tip:** Implementing a monitoring system can help track the operation of PILOT-operated relief valves in real-time, allowing for proactive adjustments and minimizing the risk of over-pressure scenarios.

Pilot operated relief valves (PORVs) play a crucial role in maintaining safety and efficiency in the oil and gas sectors. These valves utilize a pilot signal to manage the fluid pressure effectively, ensuring that the system operates within safe limits. In high-pressure environments such as oil drilling and transportation, the functionality of these valves is paramount to prevent catastrophic failures and protect both personnel and equipment.

One compelling case study in the oil industry highlights the successful implementation of PORVs in offshore drilling rigs. By integrating these valves into the pressure management systems, operators have been able to significantly reduce the risk of blowouts. This not only safeguards the environment but also enhances operational uptime. Tips for optimizing the use of PORVs include regular maintenance schedules to ensure their responsiveness and accuracy, as well as calibrating the pilot settings to match specific operational requirements.

In the gas sector, PORVs are used to regulate pressure in pipelines, mitigating the risk of leaks and explosions. A notable example can be seen in natural gas distribution networks, where accurate pressure control is vital. Tips for enhancing the efficiency of PORVs in this context involve installing pressure monitoring systems that provide real-time data, allowing for quick adjustments and preventing pressure spikes. By focusing on both technology and strategy, industries can leverage the full potential of pilot operated relief valves to achieve safer and more reliable operations.

Pilot Operated Relief Valves (PRVs) have become a crucial component in enhancing the efficiency of industrial applications, particularly when compared to conventional relief valves. The integration of Hydraulic Energy Regeneration Units (HERU) with PRVs offers notable benefits, reducing energy losses significantly, especially in high-pressure systems where overflow flow rates are critical. The research highlights how leveraging this technology can create more sustainable systems by optimizing performance through energy conservation.

When assessing the differences between pilot-operated and conventional relief valves, it’s essential to consider the operational dynamics. PRVs not only provide surge relief but also maintain pressure protection more effectively than their conventional counterparts. This is particularly important in pipeline systems where unexpected surges can lead to catastrophic failures.

Tips: To optimize the performance of relief valves in your system, regularly maintain and calibrate them to ensure they are functioning correctly. Additionally, consider incorporating advanced technologies such as HERU to further enhance energy efficiency. Another tip is to perform routine benchmarking against industry standards to remain competitive and ensure safety compliance.

In recent years, the field of pilot-operated relief valves (PORVs) has witnessed significant technological innovations aimed at enhancing safety, efficiency, and performance in industrial applications. One notable trend is the integration of smart technology into these systems, allowing for real-time monitoring and optimization of pressure relief processes. Advanced sensors and IoT connectivity enable operators to receive immediate alerts concerning valve performance, reducing the risk of malfunctions and improving response times in critical situations.

Another emerging trend is the shift towards more environmentally friendly materials and designs. Manufacturers are increasingly focusing on developing pilot-operated relief valves that comply with stringent environmental regulations, utilizing materials that minimize leakage and enhance durability. This not only contributes to a lower carbon footprint but also extends the lifecycle of the components, aligning with sustainable industrial practices. The focus on resilience and adaptability means that future PORVs will not only perform under current conditions but will also be better equipped to handle evolving industry demands and regulatory challenges.

| Dimension | Value | Trend/Innovation |

|---|---|---|

| Standard Operating Pressure (PSI) | 3000 | Increase in adaptation for high-pressure systems |

| Temperature Range (°F) | -20 to 400 | Materials innovation for extreme temperatures |

| Response Time (ms) | 20 | Development of faster actuation methods |

| Size Options (inch) | 1 to 10 | Customization for diverse industrial applications |

| Safety Factor (% above max) | 10-25 | Enhancements in safety and failure rates |

| Material Types | Stainless Steel, Alloy | Innovations in corrosion resistance |

| Maintenance Frequency (months) | 6 | Smart technology for predictive maintenance |